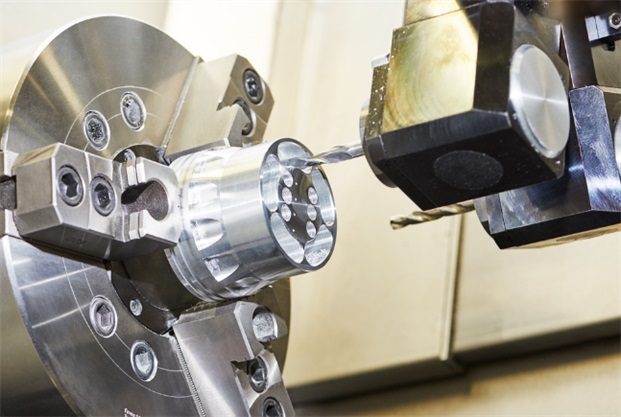

What is CNC Turning?

CNC turning center is an automatic machine with high precision and high efficiency.It has many knife tool or cutter tool, the machine tool has a wide range of machining technology performance. It can process linear cylinder, slant cylinder, arc and various threads, grooves, worm shaft and other complicated work pieces. It has linear interpolation, circular interpolation and various compensation functions, and has played a good economic effect in the batch of complex parts.

CNC machine tools can work automatically according to the arrangement processing program. The machining process, process parameters, knife tool path, displacement, cutting parameters (spindle rotation, feed, back knife) and auxiliary functions (tool change, spindle rotation, reversal, cutting liquid, and so on) are written into processing program according to the instructions and program format specified by CNC machine tools.then the contents of the program are recorded on the control medium (such as perforated paper tape, magnetic tape, disk, magnetic bubble memory), and then input into the CNC machine tool, so as to command the machine parts.

The whole process from part drawing analysis to control medium is called NC programming. The difference between the NC machine tool and the common machine tool is that the NC machine tool make the parts automatically according to the program, and the ordinary machine tools should be operated by people. As long as we change the program of machine, then we can achieve the purpose of machining different parts.